Advantages of ceramic nozzle with spring device in solid-state applications

With the increasing demand for longer lifespan and reduced cost of nozzles in the die bonding process, the application of ceramic nozzles has become more widespread. The material has evolved from using stainless steel, insulating plastics, rubber, to the current mainstream ceramic, replacing various materials in the past, which is an inevitable trend. Why has the development of ceramic nozzles been so rapid? The reason is that it possesses several key advantages that other materials lack:

1.High hardness, wear resistance, and long lifespan.

2.Insulation, non-conductive, and anti-static.

3.Corrosion resistance, high-temperature resistance, and resistance to acid and alkali.

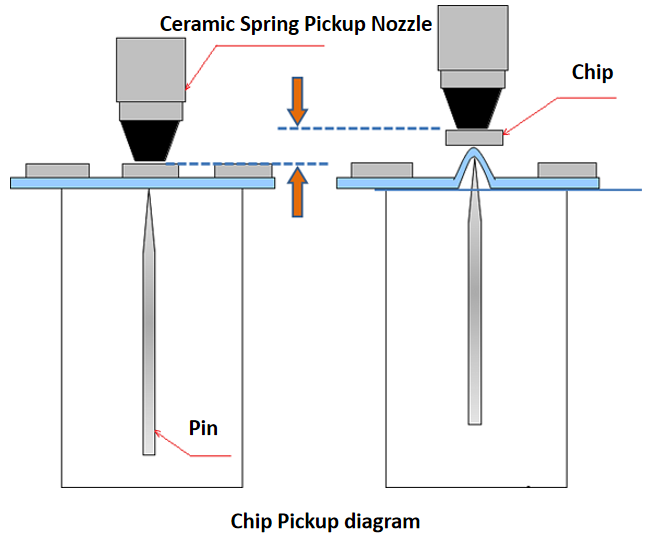

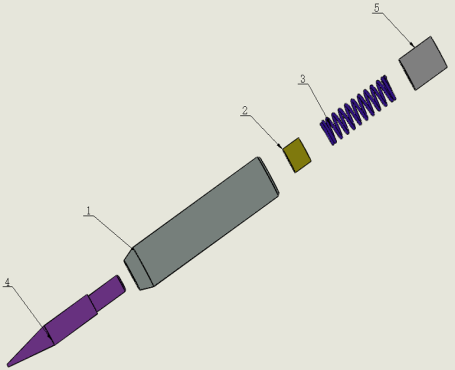

When picking up the chip, the end face of the ceramic nozzle tightly adheres to the chip surface. Due to the high hardness of ceramic material, direct rigid contact can cause chip breakage and edge chipping. To solve this problem, an adjustable elasticity needs to be added to the ceramic to prevent chip damage. Therefore, ceramic nozzles with spring devices have emerged, as shown in the figure below:

Advantages of Spring Nozzles:

1.Long lifespan, with a usage lifespan of 3-5 million chip pickups.

2.Low operating cost.

3.Low nozzle replacement frequency, saving manual adjustment time and labor costs.

4.Stable die bonding process with good consistency.